McArthur River Mine/Key Lake Mill

McArthur River is the world’s largest high-grade uranium mine, and Key Lake is the world’s largest uranium mill.

Ore grades at the McArthur River mine are 100 times the world average, which means it can produce more than 18 million pounds per year by mining only 150 to 200 tonnes of ore per day. We are the operator of both the mine and mill.

McArthur River is one of our three material uranium properties.

| Location | Saskatchewan, Canada | |

| Ownership |

69.805% – McArthur River 83.33% – Key Lake |

|

| End product | Uranium concentrates | |

| ISO certification | ISO 14001 certified | |

| Mine type | Underground | |

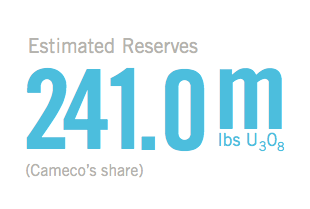

| Estimated reserves (our share) | 241.0 million pounds (proven and probable), average grade U3O8: 14.87% | |

| Estimated resources (our share) |

7.4 million pounds (measured and indicated), average grade U3O8: 4.24% 39.9 million pounds (inferred), average grade U3O8: 7.38% |

|

| Mining methods |

Primary: raiseboring Secondary: blasthole stoping, boxhole boring |

|

| Licensed capacity |

Mine: 21.0 million pounds per year Mill: 25.0 million pounds per year |

|

| Licence term | Through October 2023 | |

| Total production: (100% basis) |

2000 to 2014 1983 to 2002 |

269.7 million pounds (McArthur River/Key Lake) 209.8 million pounds (Key Lake) |

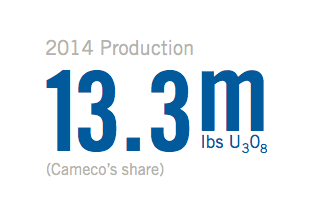

| 2014 production (our share) | 13.3 million pounds (19.1 million pounds on 100% basis) | |

| 2015 production outlook (our share) | 13.7 million pounds (19.6 million pounds on 100% basis) | |

| Estimated decommissioning cost (100% basis) |

$48 million – McArthur River $218 million – Key Lake |

|

Background

Mining methods and techniques

We use a number of innovative methods to mine the McArthur River deposit:

Ground freezing

The sandstone that overlays the deposit and basement rocks is water-bearing, with large volumes of water under significant pressure. We use ground freezing to form an impermeable wall around the area being mined. This prevents water from entering the mine, and helps stabilize weak rock formations. To date, we have isolated six mining areas with freezewalls.

Raisebore mining

Raisebore mining is an innovative non-entry approach that we adapted to meet the unique challenges at McArthur River. It involves:

- drilling a series of overlapping holes through the ore zone from a raisebore chamber in waste rock above the mineralization

- collecting the broken ore at the bottom of the raises using line-of-sight remote-controlled scoop trams, and transporting it to a grinding circuit

- once mining is complete, filling each raisebore hole with concrete

- when all the rows of raises in a chamber are complete, removing the equipment and filling the entire chamber with concrete

- starting the process again with the next raisebore chamber

McArthur River currently has six areas with delineated mineral reserves and delineated mineral resources (zones 1 to 4, zone 4 south and zone B) and two additional areas with delineated mineral resources (zone A, McArthur north). We are currently mining zone 2 and zone 4.

Zone 2 has been actively mined since production began. It is divided into four panels (panels 1, 2, 3 and 5) based on the configuration of the freezewall around the ore. As the freezewall is expanded, the inner connecting freezewalls are decommissioned in order to recover the uranium that was inaccessible around the active freeze pipes. Panel 5 represents the upper portion of zone 2, overlying part of the other panels. Mining is nearing completion in panels 1, 2 and 3, and the majority of the remaining zone 2 proven mineral reserves are in panel 5.

Zone 4 is divided into three mining areas: central, north and south. We are actively mining the central area and began mining zone 4 north in the fourth quarter of 2014.

The CNSC has granted approval for the use of two secondary extraction methods: blasthole stoping and boxhole boring.

We have used the approved mining methods to successfully extract about 272 million pounds (100% basis) since we began mining in 1999. Raisebore mining is scheduled to remain the primary extraction method over the life-of-mine.

Boxhole boring

Boxhole boring is similar to the raisebore method, but the drilling machine is located below the mineralization, so development is not required above the mineralization. This method is currently being used at a few mines around the world, but had not been used for uranium mining prior to testing at McArthur River.

Test mining to date has identified this as a viable mining option; however, only a minor amount of ore is scheduled to be extracted using this method.

Blasthole stoping

Blasthole stoping involves establishing drill access above the mineralization and extraction access below the mineralization. The area between the upper and lower access levels (the stope) is then drilled off and blasted. The broken rock is collected on the lower level and removed by line-of-sight remote-controlled scoop trams, then transported to a grinding circuit. Once a stope is mined out, it is backfilled with concrete to maintain ground stability and allow the next stope in sequence to be mined. This mining method has been used extensively in the mining industry, including uranium mining.

Blasthole stoping is planned in areas where blast holes can be accurately drilled and small stable stopes excavated without jeopardizing the freezewall integrity. We expect this method to allow for more economic recovery of ore on the periphery of the orebody, as well as smaller, lower grade areas, and we continue to study opportunities to increase the use of blasthole stoping, which would improve cost efficiency and productivity.

Initial processing

We carry out initial processing of the extracted ore at McArthur River:

- the underground circuit grinds the ore and mixes it with water to form a slurry

- the slurry is pumped 680 metres to the surface and stored in one of four ore slurry holding tanks

- it is blended and thickened, removing excess water

- the final slurry, at an average grade of 15% U3O8, is pumped into transport truck containers and shipped to Key Lake mill on an 80 kilometre all-weather road

Water from this process, including water from underground operations, is treated on the surface. Any excess treated water is released into the environment.

2014 update

Production

Production from McArthur River/Key Lake was 19.1 million pounds; our share was 13.3 million pounds. This was 4% higher than our forecast for the year as a result of a record month of production at Key Lake in December. However, annual production was 6% lower than in 2013 due to a labour disruption that resulted in an unplanned shutdown of the operations for approximately 18 days during the third quarter of 2014.

Licensing and production capacity

In 2014, the CNSC approved the EA for the Key Lake extension, a project which involves increasing our tailings capacity and Key Lake’s nominal annual production rate. We also received approval to increase the production limit at McArthur River. The licence conditions handbooks for these operations now allow:

- the Key Lake mill to produce up to 25 million pounds (100% basis) per year

- the McArthur River mine to produce up to 21 million pounds (100% basis) per year

With the approved EA, and once the Key Lake extension project is complete, mill production can be increased to closely follow production from the McArthur River mine.

McArthur River production expansion

We have been working to increase our annual production rate at McArthur River to 22 million pounds (100% basis). Since, in 2014, we received approval to produce up to 21 million pounds (100% basis) per year, we decided to file an application with the CNSC to increase licensed annual production up to 25 million pounds (100% basis) to allow flexibility to match the approved Key Lake mill capacity. The application was filed in January 2015.

In order to sustain or increase production, we must continue to successfully transition into new mine areas through mine development and investment in support infrastructure. We plan to:

- obtain all the necessary regulatory approvals

- expand the freeze plant and electrical distribution systems

- optimize the mine ventilation system

- improve our dewatering system and expand our water treatment capacity as required to mitigate capacity losses should mine development increase background water volumes

- expand the concrete distribution systems and batch plant capacity

New mining areas

New mining zones and increased mine production require increased ventilation and freeze capacity. In 2014, we continued to upgrade our electrical infrastructure on surface as part of our plan to address these future needs.

Underground, we began mining in zone 4 north during the fourth quarter of 2014.

Key Lake extension project and mill revitalization

The Key Lake mill began operating in 1983, and we continue to upgrade circuits with new technology to simplify operations and improve environmental performance. As part of the upgrades, we continued to construct a new calciner circuit, and expect to begin operating with the new calciner in 2015.

The revitalization plan is expected to allow the mill to increase its annual uranium production capability to closely follow annual production rates from the McArthur River mine.

Tailings capacity

This year, the CNSC approved the Key Lake extension EA, allowing us to deposit tailings to a higher level in the Deilmann tailing management facility. We now expect to have sufficient tailings capacity to mill all the known McArthur River mineral reserves and resources, should they be converted to reserves, with additional capacity to toll mill ore from other regional deposits.

Labour relations

The mine and mill experienced a labour disruption that resulted in an unplanned shutdown of the operations for approximately 18 days during the third quarter of 2014. On October 6, 2014, unionized employees at McArthur River and Key Lake accepted a new four-year contract that includes a 12% wage increase over the term of the agreement. The previous contract expired on December 31, 2013.

Exploration

In 2014, we completed the planned development advance of the underground exploration drifts and underground delineation drilling.

Planning for the future

Production

We plan to produce 19.6 million pounds in 2015; our share is 13.7 million pounds.

Mill revitalization

In 2015, we expect to complete installation and commissioning of the new calciner.

Exploration

In 2015, we plan to continue advancing the underground exploration drifts to the southwest and northeast directions. Additional drilling is planned underground to delineate zone A and zone B, and from surface to identify additional mineral resources in the deposit.

Managing our risks

Production at McArthur River/Key Lake poses many challenges: control of groundwater, weak rock formations, radiation protection, water inflow, mine area transitioning, and regulatory approvals. Operational experience gained since the start of production has resulted in a significant reduction in risk.

Transition to new mining areas

In order to successfully achieve the planned production schedule, we must continue to successfully transition into new mining areas, which includes mine development and investment in critical support infrastructure.

Water inflow risk

The greatest risk is production interruption from water inflows. A 2003 water inflow resulted in a three-month suspension of production. We also had a small water inflow in 2008 that did not impact production.

The consequences of another water inflow at McArthur River would depend on its magnitude, location and timing, but could include a significant interruption or reduction in production, a material increase in costs or a loss of mineral reserves.

We take the following steps to reduce the risk of inflows, but there is no guarantee that these will be successful:

- Ground freezing: Before mining, we drill freezeholes and freeze the ground to form an impermeable freezewall around the area being mined. Ground freezing reduces but does not eliminate the risk of water inflows.

- Mine development: We plan for our mine development to take place away from known groundwater sources whenever possible. In addition, we assess all planned mine development for relative risk and apply extensive additional technical and operating controls for all higher risk development.

- Pumping capacity and treatment limits: Our standard for this project is to secure pumping capacity of at least one and a half times the estimated maximum sustained inflow. We review our dewatering system and requirements at least once a year and before beginning work on any new zone.

We believe we have sufficient pumping, water treatment and surface storage capacity to handle the estimated maximum sustained inflow.

We also manage the risks listed here.