McArthur River/Key Lake

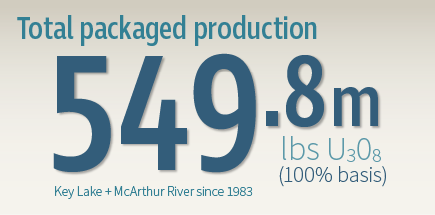

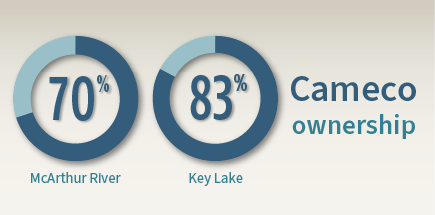

- McArthur River/Key Lake, located in northern Saskatchewan, Canada, are the world's largest high-grade uranium mine and mill.

- In service since 1999 and 1983 respectively, Cameco operates the ISO 14001 certified operations, which have collectively produced 567.9 million lbs using a variety of mining methods.

Operation

McArthur River Reserves

2025 Q3 Update

- Production

McArthur River Production

Cameco's Share (million lbs)Three months ended September 30 Six months ended September 30 2025 2024 Change 2025 2024 Change 2025 Plan 2.2 2.8 (21)% 7.2 10.6 (32)% 9.8 to 10.51 As announced in August, our outlook for production from McArthur River/Key Lake has changed. We now expect to produce between 14 million and 15 million pounds (100% basis) in 2025 (previously expected 18 million pounds).

In the third quarter of 2025, total packaged production from McArthur River and Key Lake was 3.2 million pounds (2.2 million pounds our share) compared to 4 million pounds (2.8 million pounds our share) in the third quarter of 2024. In the first nine months of the year, total packaged production from McArthur River and Key Lake was 10.3 million pounds (7.2 million pounds our share) compared to 15.2 million pounds (10.6 million pounds our share) in the first nine months of 2024. The lower packaged production is primarily due to the delays we have experienced in transitioning into new mining areas at McArthur River in 2025. As a result of these development delays at McArthur River, the Key Lake mill was shut down from September 3 through October 17, impacting production in the third quarter and the first nine months, and resulting in lower expected production for 2025.

As announced on August 28, 2025, we now expect 2025 packaged production of 14 million to 15 million pounds (9.8 to 10.5 million pounds our share).

- Labour Relations

The collective agreement with the United Steelworkers Local 8914 expires in December 2025. As such, we expect the impact risk of a labour dispute, if it were to occur, to be minimal in 2025.

Environment & Safety

Worker safety, environmental monitoring and proper decommissioning, after mining is completed, are of the utmost importance to Cameco.

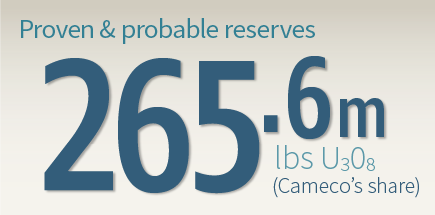

Reserves & Resources

Our mineral reserves and resources are the foundation of our company and fundamental to our success.

Caution about Forward-Looking Information

This page may contain forward-looking information that is based upon the assumptions and subject to the material risks discussed on page 2 of Cameco's most recent Quarterly MD&A.