From Ore to Yellowcake

Uranium ore is simply rock with elevated amounts of uranium in it. Once the rock has been removed by open pit or underground mining it must be milled to separate the uranium from other constituents. The milling process for uranium is similar to that used for other metals such as copper, gold or nickel.

The first step is to crush the ore and mix it with water so that it can move through a series of mill circuits.

After crushing, the ore is treated with acid in large tanks to separate the uranium from other minerals in the host rock.

The uranium is now in solution form which is then separated from the other minerals that remain as solids.

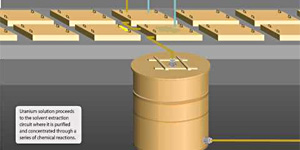

The uranium-rich solution is then purified through a solvent extraction process and returned to a solid form through chemical precipitation.

Finally, the uranium is dried. The resulting powder is uranium oxide concentrate, commonly referred to as yellowcake because it is often bright yellow.

The yellowcake is packaged into special steel drums similar in size to oil barrels. When full they weigh about 400 kilograms. Approximately 43 drums per load are hauled by truck to uranium refineries, the next stages of processing.