Environment

We recognize and embrace our responsibility to minimize our impacts on air, land, and water and to safeguard the biodiversity of surrounding ecosystems.

The following are highlights of selected priority environmental topics. Please see our 2024 Sustainability Report for more information or Our Performance for all indicator results.

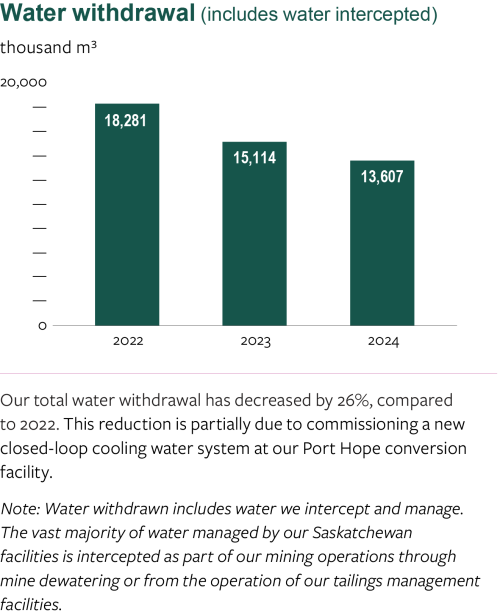

Water

Responsible water management is critical to our business. We recognize the importance of preserving this resource for the Indigenous Peoples and local communities we share it with today.

We work continuously with regulators, governments, researchers, and communities to understand possible impacts, develop best practices, and make changes that mitigate potential impacts on the environment. At our sites and facilities, we have robust water management and monitoring programs that apply to all withdrawals and discharges, and we tailor our water management practices to local uses and conditions.

Water sources and uses

The vast majority of water (groundwater, surface water, or precipitation) managed by our Saskatchewan facilities is not intentionally withdrawn for mining use but instead intercepted as part of our mining operations through mine dewatering or from the operation of our tailings management facilities. Where possible, we use this intercepted water to support our operational water requirements.

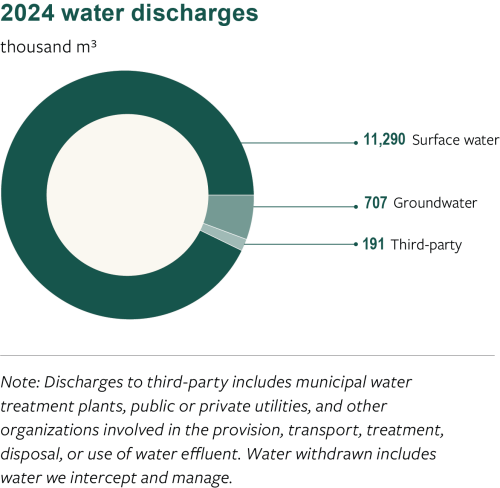

Water discharges

At Cameco, we carefully manage our treated water discharges to keep potential risks to human health and the environment as low as reasonably achievable and to comply with applicable legal and regulatory requirements. To protect people and the environment, we have implemented management tools consistent with our overall management approach, which include:

- inflow reduction

- water segregation

- water treatment

Discharge monitoring

We have monitoring programs to verify that human health and the environment remain protected in the vicinity of our operations. We adhere to regulatory requirements from the Canadian Nuclear Safety Commission, the Saskatchewan Ministry of Environment, and Environment and Climate Change Canada.

Watershed stewardship

As part of our environmental monitoring programs, we take more than 22,000 samples related to water quality each year. We collect water samples at or immediately downstream of our operations (near-field), in close proximities to our operations (mid-field), and at locations at a further distance (five to ten kilometres) from our operations (far-field). These samples are sent for testing for different chemicals and other indicators of quality to both internal laboratories and an accredited third-party facility.

Learn more about our watershed stewardship

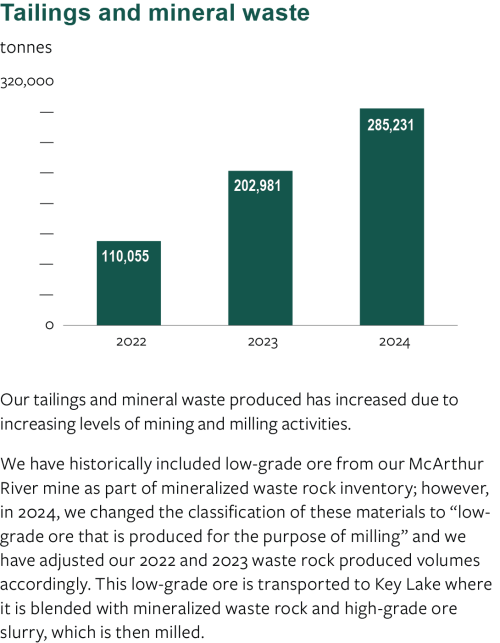

Tailings Management

Tailings and waste rock are an inevitable byproduct of most mining activities. Responsible and safe management of mining waste streams is critical to protecting the environment as well as the safety of our workers, operations and communities.

To strengthen our tailings management approach, we seek to apply lessons learned from industry incidents and are committed to continuous improvement.

Milling of uranium ore produces tailings, which are primarily composed of the residual rock left after the uranium is recovered, mineral precipitates, and minor amounts of processing chemicals.

These tailings are safely stored on-site within engineered tailings management facilities. The annual tonnage of tailings produced varies and is dependent on the ore grade and the production rate. The high uranium grade of our mines in northern Saskatchewan means we obtain more uranium per tonne of rock processed than low grade facilities, resulting in lower amounts of tailings per unit of uranium produced.

Tailings management is relevant only to our Canadian operations because the in situ recovery method used in our US operations does not produce tailings or waste rock. We have four tailings facilities in Saskatchewan, two at our Key Lake site and two at our Rabbit Lake site. Both Key Lake and Rabbit Lake have one active in-pit tailings facility (in-pit facility) and one above-ground tailings management facility (above-ground tailings facility).

We employ broad, risk-based practices to effectively manage our tailings and mine waste storage facilities. We have accountability at the highest level of the organization, and systems and procedures that follow best practices contained in industry recognized standards.

Learn more about our tailings management practices

GHG Emissions

At Cameco, we recognize the critical nature of the fight against climate change and that there are risks and opportunities associated with climate change and the energy transition as we seek to achieve our strategic plan.

We are committed to addressing these risks and taking advantage of the opportunities in a manner that we expect to add long-term value for our stakeholders.

Our GHG emissions are directly related to the type and amount of energy we consume. Cameco quantifies emissions following the globally recognized GHG Protocol Corporate Standard.

Scope 1

~131,381 tCO2e

Our Scope 1 emissions are primarily associated with the consumption of propane and natural gas for heating. We also use diesel and gasoline to operate heavy-duty and light vehicles across our operations, and relatively small quantities of diesel for back-up power generation. We release small quantities of GHG emissions from chemical processes during milling and from Cameco operated landfills.

Scope 2

~178,306 tCO2e

All Scope 2 emissions arise from electricity consumption and correlate to the emissions intensity of grid-supplied electricity in the regions we operate. Our main source of power for our northern Saskatchewan operations is hydroelectric. However, our location-based Scope 2 emissions use a single emissions factor that reflects the energy mix from the entire provincial grid in Saskatchewan and Ontario (data in the performance table).

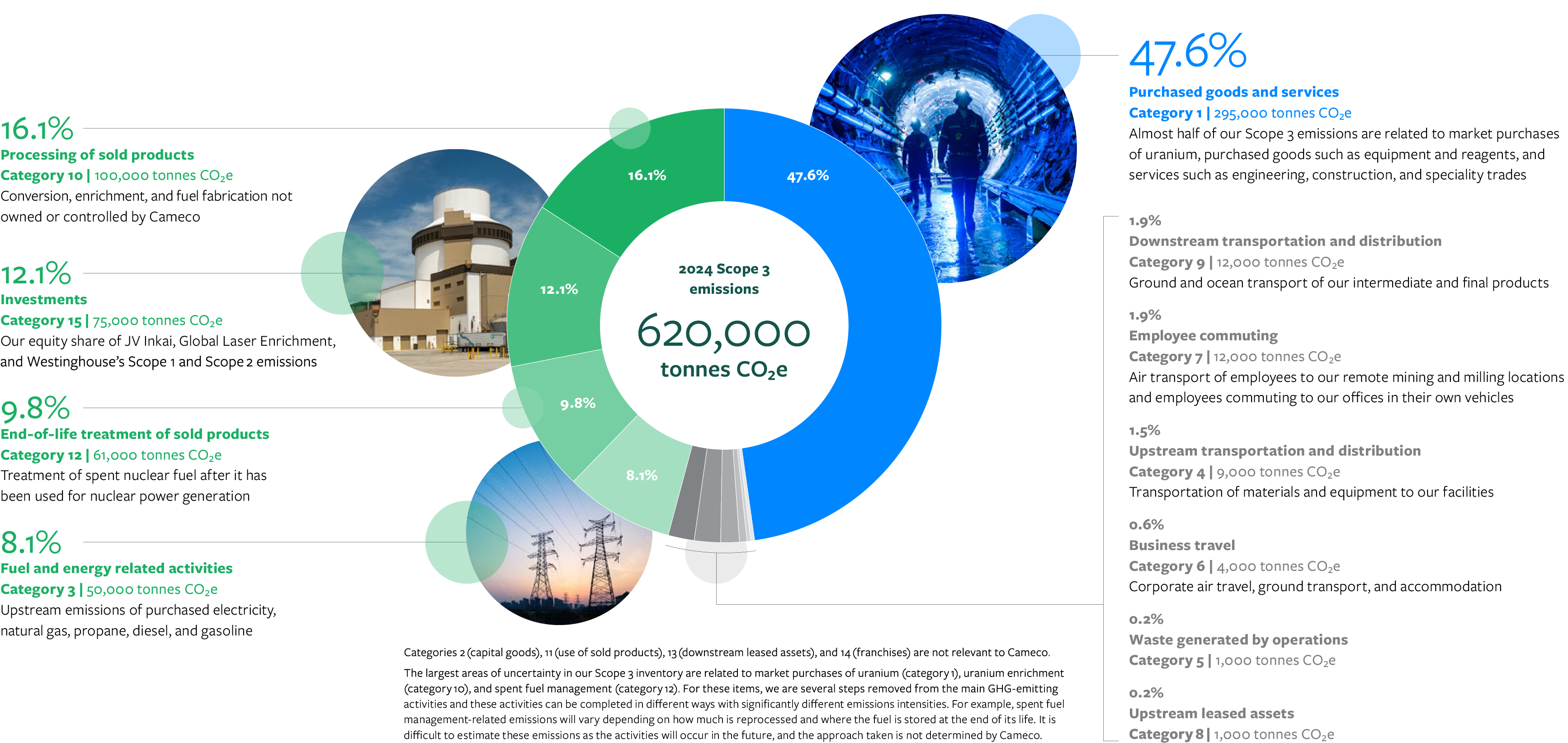

Scope 3

~620,000 tCO2e

Scope 3 emissions are not covered in Scope 1 or 2 and result from activities that occur in our value chain. Building on our work from last year, where we reported our total Scope 3 emissions in our 2023 Sustainability Report, we are now reporting our Scope 3 emissions broken down by category as noted below.

Scope 3 Emissions by Category

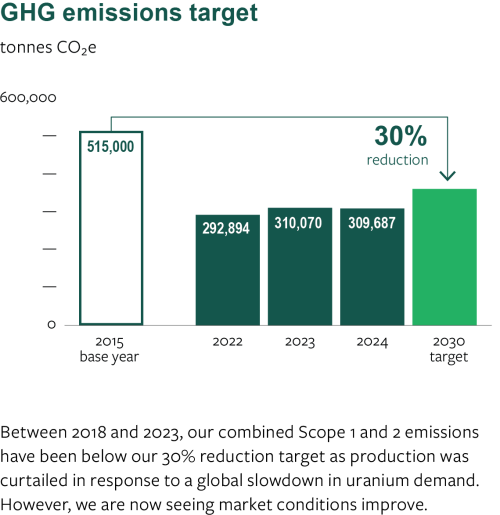

Our GHG reduction target

Our 30 by 30 reduction target means that we will work to permanently reduce our Scope 1 and Scope 2 GHG emissions by 155,000 tCO₂e across our operated facilities by 2030. Under this target, we will also strive to achieve a minimum reduction of 30,000 tCO₂e from Scope 1 emissions specifically. This sub-target demonstrates our commitment to reducing the direct carbon footprint of Cameco facilities and maintain alignment with facility-based emissions reductions required by regulators.

Decommissioning

Our commitment to protecting the environment and the needs of the communities around our operations extends to the full life-cycle of our mines and facilities. This includes planning for decommissioning and preparing our sites for permanent closure.

Conceptual plans for each site describes activities required to reclaim the site to defined final end-state objectives, after the operating life of a facility. The plan includes a preliminary cost estimate for labour, materials, equipment, waste management, regulatory approvals, monitoring, and administration to carry out the plan.

At the end of 2024, our estimated future decommissioning and reclamation costs (total and undiscounted) for our assets were approximately $1.38 billion, with some revised estimates still subject to regulatory approval. We have recorded accounting provisions for the discounted value of these estimates, and every quarter, we update these estimates based on new cash flow estimates, discount, and inflation rates. To verify we can pay for these future obligations, we have financial assurances of $1.13 billion (in the form of letters of credit or surety bonds to satisfy current regulatory requirements), which is based on previously approved preliminary decommissioning estimates and will increase once the regulator approves all revised estimates and confirms the value of financial assurances required. The expected timing for these costs is based on each mine or fuel services facility’s expected operating life. Our required costs for decommissioning and reclamation in each of the next five years are not expected to be material.

Proactive reclamation

If part of an active site is ready for reclamation before the full site reaches the end of its life, we can proceed proactively with reclamation work on that area. Some of the projects we have undertaken in the last few years include:

Water restoration in the U.S.

In 2024, one mine unit had a final restoration report and decommissioning plan submitted. Five mine units are undergoing reverse osmosis treatment, six mine units are currently in stability, and two mine units are preparing to enter the stability stage.

Waste rock pile revegetation at Key Lake

The Key Lake operation continues to undergo progressive reclamation. At one of Key Lake’s waste rock piles, we have been successful at revegetating a portion of a covered pile through the application of local lake bottom organic sediments as a nutrient source and seed bank to establish shrubs, bushes, and trees.

Learn more

- 2024 Sustainability Report - Environment

- Our Performance for all indicator results.

| Environment and safety at our uranium operations | Environment and safety at our fuel services business |