Case Study

Water cover prevents unconsolidated tailings from freezing

In-pit tailings management facilities, pioneered by Cameco, are recognized as a best practice in tailings management around the world.

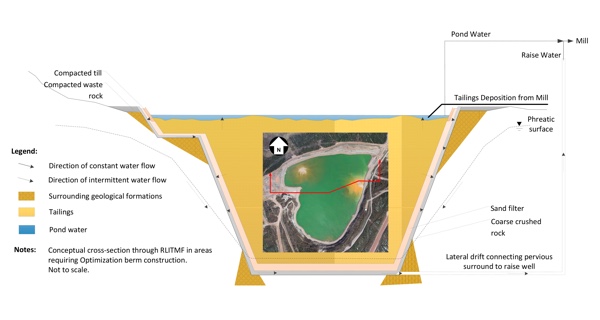

At the Rabbit Lake operation in northern Saskatchewan, a mined-out pit stores tailings. The pit walls are lined with a layer of coarse rock, which ensures good drainage, and a layer of sand traps fines from the tailings as they consolidate for safe storage in the Rabbit Lake In-Pit Tailings Management Facility (RLITMF).

“The design is superb from a geotechnical point of view,” says Pat Landine, chief geo-environmental engineer with Cameco’s safety, health, environment and quality department. “In a warm climate, you get excellent drainage and consolidation of the tailings. But in a colder climate, when you have a drained surface, the tailings will freeze.”

Layers of frozen tailings accumulate like a layer cake, one layer for each winter. These unconsolidated (low-density) tailings cause the facility to fill up more quickly, resulting in a loss of disposal space.

Rabbit Lake in-pit tailings management facility (RLITMF)

To prevent this issue, a pond was established on the surface of the RLITMF in the winter of 2012–13. The pervious surround was modified by making the sand filter thinner and adding a zone of compacted till to create a barrier that retains water, thereby creating a pond.

Landine explains the basic concept: “If the water in a slough is 50 centimetres deep, the whole thing will freeze. But if the slough is two metres deep, and the ice forms one metre deep, the bottom of the slough doesn’t freeze.”

In addition to introducing the surface pond, which allows tailings to consolidate below the surface, the team adjusted the deposition method. Instead of discharging tailings at the edge of the pit, the pipeline now extends to the centre of the pit where tailings are deposited below the water surface.

“The warm tailings are discharged into the pond, so we’re actually adding heat below the surface,” says Landine. “We brought that idea, known as sub-aqueous deposition, from Key Lake to Rabbit Lake. But the Rabbit Lake pond is shallow – no more than two metres deep compared to Key Lake’s Deilmann facility where it’s 40 metres deep.”

The adjustments at Rabbit Lake have resulted in a 35% reduction in the amount of space occupied by newly placed tailings.

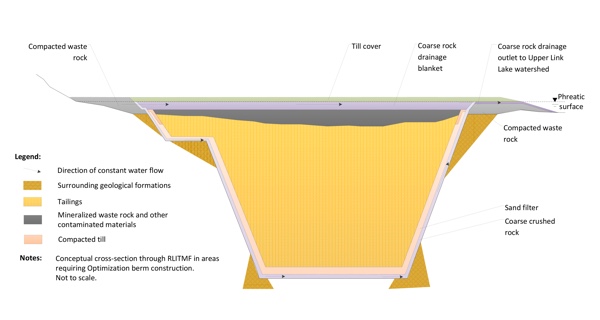

Before decommissioning of the RLITMF can take place, full consolidation of the tailings must be achieved. To that end, an electrical resistance heating plan has been devised to thaw the layers which formed before the surface pond was established. Electrodes implanted in the layers will carry an electrical current to warm the tailings and allow consolidation.