McArthur River/Key Lake

McArthur River is the world's largest, high-grade uranium mine, and Key Lake is the largest uranium mill in the world.

Ore grades at the McArthur River mine are 100 times the world average, which means it can produce more than 18 million pounds per year by mining only 150 to 200 tonnes of ore per day. We are the operator.

McArthur River is one of our three material uranium properties.

| Location | Saskatchewan, Canada |

| Ownership | 69.805% – McArthur River 83.33% – Key Lake |

| End product | uranium concentrates |

| ISO certification | ISO 14001 certified |

| Mine type | underground |

| Estimated reserves (our share) |

226.2 million pounds (proven and probable) average grade U3O8: 16.89% |

| Estimated resources (our share) |

51.0 million pounds (measured and indicated) average grade U3O8: 17.63% 60.3 million pounds (inferred) average grade U3O8: 9.67% |

| Mining methods | currently: raiseboring pending regulatory approval: blasthole stoping under development: boxhole boring |

| Licensed capacity | mine and mill: 18.7 million pounds per year (can be exceeded – see Production flexibility) |

| Total production 2000 to 2011 | 211 million pounds (McArthur River/Key Lake) (100% basis) |

| 1983 to 2002 | 209.8 million pounds (Key Lake) (100% basis) |

| 2011 production | 13.9 million pounds (our share) |

| 2012 forecast production | 13.1 million pounds (our share) |

| Estimated decommissioning cost | $36.1 million – McArthur River $120.7 million – Key Lake |

Background

Production flexibility

Our operating licences for Key Lake mill and McArthur River mine were amended in 2009 and 2010, giving us flexibility in our annual licensed production limit. As long as average annual production does not exceed 18.7 million pounds per year, these amendments allow:

- Key Lake mill to produce up to 20.4 million pounds (100% basis) per year

- McArthur River to produce up to 21 million pounds (100% basis) per year

If production is lower than 18.7 million pounds in any year, we can produce more in future years until we recover the shortfall. We still have the opportunity to recover past production shortfalls of about 2.5 million pounds (100% basis) at Key Lake mill and about 3.5 million pounds (100% basis) at McArthur River.

Mining methods and techniques

We use a number of innovative methods and techniques to mine the McArthur River deposit:

Ground freezing

The sandstone that overlays the deposit and basement rocks is water-bearing, with large volumes of water under significant pressure. We use ground freezing to form an impermeable wall around the area being mined. This prevents water from entering the mine, and helps stabilize weak rock formations.

In 2009, we developed an innovative, cathedral-shaped freezewall around zone 2, panel 5, allowing us to develop tunnels above and below the orebody. We expect this innovation will allow us to continue using raisebore mining as the main mining method at McArthur River and improve production efficiencies as we transition to other areas of the mine (see Planning for the future – New mining zones).

Raisebore mining

Raisebore mining is an innovative non-entry approach that we adapted to meet the unique challenges at McArthur River. It involves:

- drilling a series of overlapping holes through the ore zone from a raisebore chamber in waste rock above the ore

- collecting the broken ore at the bottom of the raises using line-of-sight remote-controlled scoop trams, and transporting it to a grinding circuit

- filling each raisebore hole with concrete once mining is complete

- removing the equipment and filling the entire chamber with concrete when all the rows of raises in a chamber are complete

- starting the process again with the next raisebore chamber

We have used the raisebore mining method to successfully extract about 210 million pounds (100% basis) since we began mining in 1999.

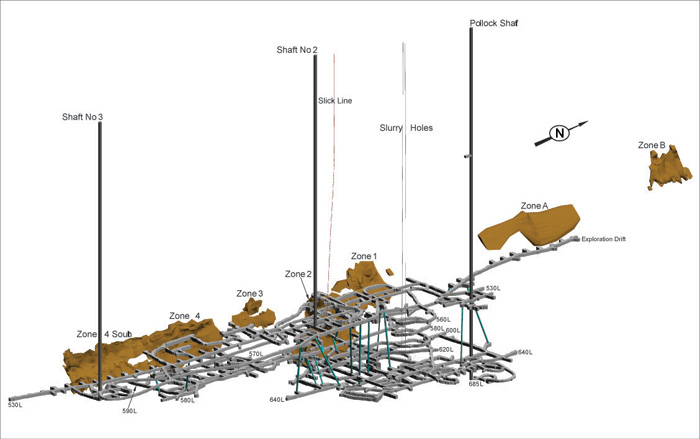

McArthur River currently has four zones with delineated mineral reserves (zones 1 to 4). Parts of zones 1, 2, 3 and 4 also have mineral resources. In addition, zones A and B to the north contain mineral resources.

We have mined from zone 2 since the mine started production. Zone 2 is divided into four panels (panels 1, 2, 3 and 5). Until late 2009, all mine production was from panels 1, 2 and 3, and there are still limited reserves that we will extract from these panels in the next few years. Panel 5 represents the upper portion of zone 2, overlying a portion of the other panels.

We successfully transitioned to panel 5 in 2009, the first time development has been accomplished through the unconformity into the Athabasca sandstone.

In late 2010, we brought the lower mining area of zone 4 into production.

Boxhole boring

Given our success with the cathedral-shaped freezewall around zone 2, panel 5, the use of boxhole boring in our mine plan has been significantly narrowed in scope. We expect to be able to continue using raisebore mining as our main mining method for McArthur River.

Boxhole boring is similar to the raisebore method, but the drilling machine is located below the orebody, so development is not required above the orebody. This method is currently being used at only a few mines around the world, but has not been used for uranium mining.

Boxhole boring poses some technical challenges. We will continue to test this method in 2012; however, we expect it will only be used as a secondary method, in areas where we determine raiseboring is not feasible. Boxhole boring may not be as productive as the raisebore method, but we will be able to determine this more accurately once we have fully developed and tested the method at McArthur River.

Blasthole stoping

Blasthole stoping involves establishing drill access above the ore and extraction access below the ore. The area between the upper and lower access levels (the stope) is then drilled off and blasted. The broken rock and ore are collected on the lower level and removed by line-of-sight remote-controlled scoop trams, then transported to a grinding circuit. Once a stope is mined out, it is backfilled with concrete to maintain ground stability and allow the next stope in sequence to be mined. This mining method has been used extensively in the mining industry, including for mining uranium.

Blasthole stoping is being evaluated for the recovery of small isolated, lower grade ore zones away from the freezewalls and where raisebore or boxhole boring is uneconomic or impractical. We mined our first blasthole stope in the fourth quarter of 2011, in lower zone 4, with good productivity.

2011 update

Production

Our share of production in 2011 was 5% higher than our target of 13.3 million pounds, and the same as 2010.

At McArthur River and Key Lake we matched our production record set in 2010, realizing benefits under the production flexibility amendments to the McArthur River and Key Lake operating licences (see Production flexibility). Our revitalization program has improved the efficiency and reliability of equipment at the Key Lake mill, which had record monthly production in the latter part of the year.

New mining areas

Upper zone 4 – we began drilling for the freezewall required to bring the upper mining area of zone 4 into production.

Mill revitalization

The Key Lake mill began operating in 1983. We are revitalizing the mill to ensure sustained reliable production and increase our uranium production capability.

The Key Lake revitalization plan includes upgrading circuits with new technology to simplify operations and improve environmental performance. After the mill is revitalized, annual production will depend mainly on mine production. As part of this plan, we replaced the acid, steam and oxygen plants.

At the end of 2011, construction of all three plants was complete. The steam plant was commissioned at year end and the oxygen plant was commissioned in early 2012. We have started commissioning the acid plant.

Tailings capacity

The regulator approved the guidelines for our Key Lake extension project, which proposes to:

- allow continued processing of ore from the McArthur River mine and other potential mine developments

- increase long-term capacity of the Deilmann tailings management facility by allowing us to deposit tailings to a higher elevation

- increase annual mill production capacity to 25 million pounds (100% basis)

We are currently drafting the environmental impact study for submission to the regulator as part of the environmental assessment process. This year we:

- completed the detailed design for the stabilization of the Deilmann tailings management facility pitwalls

- relocated the infrastructure necessary to allow us to flatten the slope of the pitwalls

- continued our work on the environmental assessment for the Key Lake extension project

McArthur River extension

In addition to the exploration work discussed below, we advanced feasibility work on the McArthur River extension project this year. This is a multi-year project to safely expand the underground mine and develop new mining areas.

Our plan is to:

- increase average annual production at the mine from 18.7 million pounds (100% basis) to 22 million pounds (100% basis)

- construct the infrastructure necessary to support production at this level

- further delineate mineral resources to the north and south of the current mining operations

An environmental assessment is required for the potential increase in production. Other work on this project will be approved through regular licensing activities.

Exploration

As part of the McArthur River extension, we advanced the exploration drifts to zones A and B, north of current mining operations, and were successful in upgrading the majority of the zone B inferred mineral resources to the indicated category based on surface drilling. This area continues to show promise.

Planning for the future

Production

We expect our share of production to be 13.1 million pounds in 2012 and we will continue to look for opportunities to take advantage of the production flexibility provision in our licences.

New mining zones

Zone 4 – In 2012, we will continue the drilling to install the freezewall required to bring the upper mining area of zone 4 into production. We expect to start freezing upper zone 4 in 2013 and begin production from this area in 2014.

We expect to use raisebore mining in this area, applying the ground freezing experience we gained in zone 2, panel 5. This should significantly improve production efficiencies compared to boxhole boring.

Mill revitalization

In 2012, we expect to:

- complete the commissioning of the new acid plant

- begin work for the construction of a new electrical substation and calciner

Tailings capacity

In 2012, we expect to:

- begin to flatten the slope of the Deilmann tailings management facility pitwalls

- advance the environmental assessment for the Key Lake extension project. We expect to submit the draft environmental impact statement to the regulators by the end of the second quarter. Comments on the draft are expected before year end.

Exploration

In 2012, we plan to continue advancing the underground exploration drift to the south of the current mining areas. We also plan to test, from surface, along the entire length of the mineralized zone to identify additional mineral resources.

Managing our risks

Production at McArthur River/Key Lake poses many challenges: control of groundwater, weak rock formations, radiation protection, water inflow, mining method uncertainty and changes to productivity, mine transitioning, regulatory approvals, tailings capacity, reliability of facilities at Key Lake, surface and underground fires. Operational experience gained since the start of production has resulted in a significant reduction in risk.

Water inflow risk

The greatest risk is production interruption from water inflows. A 2003 water inflow resulted in a three-month suspension of production. We also had a small water inflow in 2008 that did not impact production.

The consequences of another water inflow at McArthur River would depend on its magnitude, location and timing, but could include a significant interruption or reduction in production, a material increase in costs or a loss of mineral reserves.

We take the following steps to reduce the risk of inflows, but there is no guarantee that these will be successful:

- Ground freezing: Before mining, we drill freezeholes and freeze the ground to form an impermeable freezewall around the area being mined. Ground freezing reduces but does not eliminate the risk of water inflows.

- Mine development: We plan for our mine development to take place away from known groundwater sources whenever possible. In addition, we assess all planned mine development for relative risk, and apply extensive additional technical and operating controls for all higher risk development.

- Pumping capacity and treatment limits: Our standard for this project is to secure pumping capacity of at least one and a half times the estimated maximum sustained inflow. We review our dewatering system and requirements at least once a year and before beginning work on any new zone. We believe we have sufficient pumping, water treatment and surface storage capacity to handle the estimated maximum sustained inflow.

Key Lake tailings capacity risk

Tailings from processing McArthur River ore are deposited in the Deilmann tailings management facility. At current production rates, the licensed capacity of the Deilmann tailings management facility is about six years, assuming we experience only minor losses in storage capacity due to sloughing from the pitwalls. Significant sloughing could constrain McArthur River production.

Sloughing of material from the pitwalls in the past has resulted in the loss of capacity. Technical studies show that stabilizing and reducing water levels in the pit enhances the stability of the pitwalls and reduces the risk of sloughing. We doubled our dewatering treatment capacity, allowing us to stabilize the water level in the pit. The water level has been gradually reduced over the past three and a half years.

In 2009, regulators approved our plan for the long-term stabilization of the Deilmann tailings management facility pitwalls. We are implementing the plan, and expect it will take approximately three years to complete the work.

We have also looked at options for long-term storage of tailings at Key Lake. We are proceeding with the environmental assessment to support an application for regulatory approval to deposit tailings in the Deilmann tailings management facility to a much higher level. This would provide us with enough tailings capacity to potentially mill a volume equal to all the known mineral reserves and resources from McArthur River and additional capacity to toll mill ore from other regional deposits.

We also manage the risks listed here.